to report «iusnews»; From Calculator to Collaborator: 4 Surprising Ways AI is Redefining Mechanical Engineering

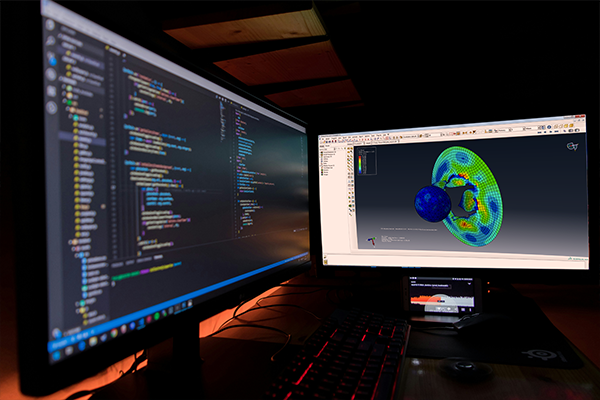

Artificial Intelligence (AI) is no longer just a futuristic buzzword — it has become a practical tool that is reshaping how mechanical engineers design, simulate, and optimize mechanical systems. From CAD automation to predictive maintenance, AI technologies are now embedded in every stage of the engineering workflow, enabling faster, smarter, and more creative problem-solving.

From Traditional Engineering to Intelligent Design

Mechanical engineering has always been driven by logic, mathematics, and physical laws. But as designs grow more complex and simulation data multiplies, traditional workflows often become too slow and costly. AI introduces a paradigm shift by allowing computers to learn patterns from data and make intelligent predictions. This means that instead of running hundreds of simulations manually, engineers can train a model once and use it to predict new outcomes almost instantly.

Machine Learning (ML) and Deep Learning (DL) — subsets of AI — are now used to identify design correlations, automate repetitive tasks, and optimize models far beyond what human intuition alone could achieve. Generative design, for instance, uses AI algorithms to explore thousands of possible geometries automatically, considering material properties, loads, and performance constraints. The result: lighter, stronger, and more efficient components developed in a fraction of the time.

1. AI Is More Than a Tool—It's a Creative Partner

In the past, the conceptual design phase was limited by human imagination, experience, and time. Engineers could only test a handful of design variations before practical constraints forced them to choose a direction. AI, particularly generative design, has shattered these limits.

By inputting parameters such as weight, cost, materials, and strength, engineers can now ask AI systems to explore thousands of design alternatives—each optimized for specific performance criteria. Instead of spending weeks refining a single model, teams can instantly visualize options that balance performance and manufacturability.

For example, aerospace engineers have used generative AI to develop lightweight components that maintain structural integrity while reducing fuel consumption. Many of these designs resemble organic shapes found in nature, illustrating how AI can mimic evolutionary efficiency to create truly novel solutions.

This is not just about optimization—it’s about discovery. AI acts as a co-creator, proposing design directions that humans might never have considered. In many cases, it can cut iteration cycles by up to 50%, allowing engineers to focus more on creativity and less on computation.

2. AI Provides “Superhuman” Quality Control

Quality control has long been one of the most challenging and labor-intensive aspects of mechanical engineering. Traditional inspection methods rely heavily on human judgment, which, while skilled, can be inconsistent and slow—especially in high-volume production environments.

Now comes AI-driven computer vision, a technology that leverages deep learning models trained on massive image datasets to spot even the smallest surface flaws—like micro-scratches, porosity, dents, or misalignments—with precision far beyond human capability. These systems inspect and interpret components in real time, identifying defects within milliseconds.

In practice, industries such as automotive manufacturing have adopted AI-based visual inspection systems that cut defect rates by more than 20%, saving millions through reduced rework and fewer warranty claims. When combined with IoT-enabled sensors, they can also track process conditions continuously, guaranteeing consistent quality across every production phase.

AI isn’t just speeding up defect detection—it’s redefining what quality control means. The outcome is not only higher product reliability but also a data-driven culture of continuous improvement built on instant insights and adaptive feedback.

If you’re interested in exploring practical applications and tools for implementing these technologies, check this blog on AI in mechanical engineering — it breaks down real-world case studies and video examples that show how these concepts come alive in the modern engineering workflow.

3. AI Is Shifting Maintenance from Reactive to Predictive

Few things are more costly than unexpected equipment downtime. Traditional maintenance models are reactive—you fix machines when they break. This approach not only disrupts production but can also lead to cascading failures and costly emergency repairs.

AI is transforming maintenance into a predictive science. By analyzing sensor data from machines—vibration levels, temperature fluctuations, power consumption, and acoustic signatures—AI can detect subtle patterns that indicate an impending failure long before it occurs.

For example, in a smart factory setting, AI systems might detect a slight increase in motor vibration and automatically flag it for inspection, predicting that a bearing will fail within 200 operating hours. Maintenance can then be scheduled during planned downtime, preventing costly interruptions.

This predictive maintenance model not only improves uptime but also extends equipment life and optimizes inventory management, since spare parts are replaced only when truly needed. Over time, AI’s insights evolve into a strategic asset, allowing engineers to make data-driven decisions about asset utilization and process improvement.

4. AI Gives Products a “Digital Twin” for Lifetime Optimization

Among all AI-driven advancements, few are as transformative as the digital twin. A digital twin is a virtual replica of a physical system—an engine, a manufacturing line, or even an entire facility—constantly updated with real-world operational data.

This digital counterpart mirrors every action, wear pattern, and environmental condition experienced by the physical product. Engineers can use it to run simulations, forecast failures, and optimize performance without interrupting actual operations.

Imagine a turbine manufacturer that monitors a fleet of engines through digital twins. By simulating different usage scenarios, the company can predict which components will wear out fastest, plan proactive maintenance, and even adjust the next generation of designs based on real usage data.

This creates a continuous feedback loop—a learning system where every deployed product informs future innovation. It bridges the gap between design, manufacturing, and operation, turning mechanical engineering into a living, evolving discipline rather than a linear process.

The Future: Collaboration, Not Replacement

AI’s expanding role in mechanical engineering isn’t about replacing human expertise—it’s about amplifying it. Machines are unmatched in data processing, pattern recognition, and precision, while engineers bring creativity, intuition, and real-world judgment to the table.

The real advantage lies in merging these strengths. Engineers who learn to work *with* AI—as collaborators rather than mere users—will design more efficient systems, cut down on material waste, and accelerate the pace of innovation.

In the coming years, AI will be embedded even deeper into engineering workflows:

* Generative design systems will automatically adjust to new materials and constraints.

* Digital twins will link design, manufacturing, and supply chains in real time.

* Self-optimizing factories will use autonomous AI to improve productivity continuously.

The question is no longer *whether* AI will transform mechanical engineering, but *to what extent*. What remains clear is that those who treat AI as a creative partner—not a rival—will lead the next generation of mechanical innovation.

Ten years from now, the role of Artificial Intelligence in engineering will be so deeply integrated that it will no longer feel like a separate technology—it will simply be how engineering is done. The design, simulation, manufacturing, and maintenance processes will evolve into fully intelligent ecosystems, where data continuously flows between digital models and physical systems. Engineers will no longer start from scratch; they’ll begin projects in collaboration with AI systems that already understand performance goals, material behavior, and regulatory constraints. Generative design tools will evolve from merely suggesting optimized shapes to autonomously proposing entire systems—complete assemblies that balance structural efficiency, manufacturability, sustainability, and cost. These designs will adapt dynamically as new materials and environmental data become available. Simulation will be almost instantaneous, powered by physics-informed neural networks capable of predicting outcomes with near-zero computational delay. Traditional finite element analysis will still exist, but mostly for validation, as engineers will rely on AI models that learn continuously from real-world performance data collected through sensors and IoT networks.

Manufacturing will undergo its own revolution. Smart factories will operate as self-optimizing organisms, using AI to coordinate supply chains, predict maintenance needs, and reconfigure production lines without human intervention. Engineers will oversee rather than micromanage, guiding AI systems through ethical, creative, and safety-related decisions. Robotics, augmented reality (AR), and AI will merge seamlessly—allowing engineers to design in virtual spaces where digital twins mirror every movement in real-time. Field engineers might wear lightweight AR glasses that visualize stresses, flow patterns, or temperature gradients on actual machinery, powered by live AI analysis.

The engineering profession itself will also transform. Instead of specializing purely in mechanical, civil, or electrical domains, future engineers will be hybrid thinkers fluent in data science, algorithm design, and system integration. AI will become an intellectual partner—handling routine calculations and simulations—while humans focus on innovation, ethics, and interdisciplinary problem-solving. Education will adapt too: future engineering students will train on collaborative AI platforms that simulate real-world projects and learn alongside them.

By 2035, the phrase “AI tools in engineering” may sound outdated because every engineering tool will inherently include AI. The challenge won’t be how to use AI—but how to use it responsibly, transparently, and creatively. Those who embrace it as a co-engineer, rather than a replacement, will define the next era of intelligent, sustainable, and adaptive design.